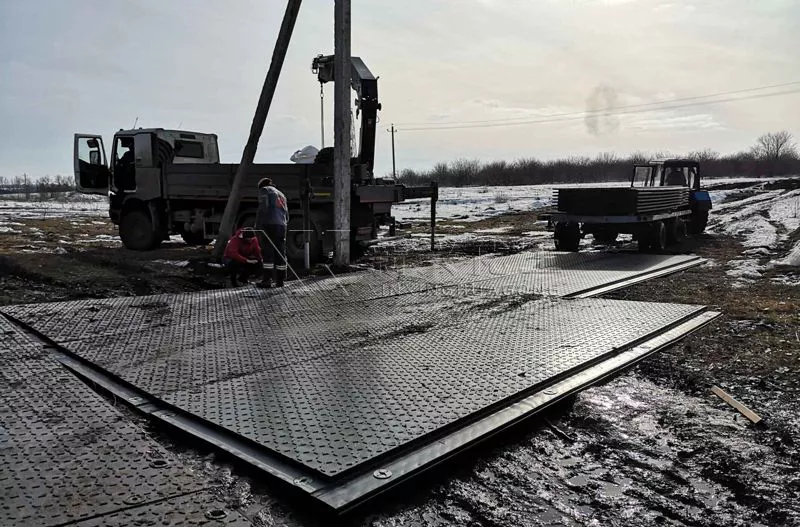

The Oil Rig Mat is available in the size 6130x2130x88mm thick and weighs 630kg. Each mat is equipped with an over-lap lip on two sides abd two under-lab lips on the opposite two sides which create the interlocking joint when two or more mats are connected.

Product introduction

The Oil Rig Mat is available in the size 6130x2130x88mm thick and weighs 630kg. Each mat is equipped with an over-lap lip on two sides abd two under-lab lips on the opposite two sides which create the interlocking joint when two or more mats are connected. Along the perimeter of the mats there are 12 threaded inserts bonded into the mats and 12 open pocket holes that are used when locking the mats securely together with the bolt connector assembly.

Our Oil Rig Mat solutions are engineered to provide robust and stable support for oil rig operations. These mats are essential for maintaining a safe and efficient working environment on any oil rig site.

We offer specialized Oil Drilling Rig Mats designed to withstand the heavy loads and harsh conditions typical of drilling operations. These mats ensure a secure foundation, preventing ground subsidence and equipment instability. In addition to our oil-specific solutions, our range of Drilling Rig Mats caters to various drilling applications. Whether for oil, gas, or other drilling activities, these mats deliver exceptional durability and performance, ensuring the safety and effectiveness of your operations.

When choosing oil rig mats, buyers and project managers usually focus on the following performance aspects:

Load-Bearing Strength

Capable of supporting extreme weights, often exceeding 100 tonnes, depending on the material.

Essential for drilling rigs, cranes, and oversized vehicles.

Durability & Weather Resistance

Built to withstand harsh conditions such as heavy rain, snow, ice, and extreme temperatures.

UV-resistant and rot-resistant for long service life in outdoor environments.

Material Options

Wood Mats (Timber Rig Mats): Traditional choice, cost-effective, widely available.

Composite Mats: Lighter, longer-lasting, resistant to rot and moisture absorption.

Steel-Framed Mats: Superior strength for heavy-duty applications and extended lifespan.

Safety Features

Non-slip traction surfaces for machinery and worker safety.

Reduced ground instability to prevent accidents and downtime.

Sustainability

Many composite and timber mats are made from recycled or sustainably sourced materials.

Reusable multiple times, reducing long-term waste and costs.

Ease of Installation and Transport

Designed with lifting points or forklift slots for quick deployment.

Stackable for efficient storage and transport.

Oil rig mats are widely used across industries where ground stability and safety are priorities. Typical applications include:

Oil & Gas Drilling Sites

Provide stable platforms for drilling rigs, pumps, and heavy machinery.

Pipeline and Utility Projects

Create access roads for trucks and protect underground utilities during excavation.

Construction and Infrastructure

Ensure safe operation of cranes, excavators, and transport vehicles on unstable terrain.

Renewable Energy Projects

Support wind turbine installation, solar farms, and hydroelectric construction.

Temporary Access Roads

Prevent vehicles from sinking in muddy or environmentally sensitive areas.

Protect the Environment

Minimize soil erosion, prevent contamination, and reduce damage to wetlands or vegetation.

Increase Safety

Provide stable ground to reduce equipment tipping or worker injuries.

Cost Savings

Durable, reusable mats lower replacement costs and reduce downtime caused by unstable terrain.

Versatility

Suitable for heavy industrial operations, events, and temporary access.

When selecting oil rig mats for your project, consider:

Load requirements: Match mat strength to the heaviest equipment used.

Terrain type: Wetlands, rocky ground, or soft soil may require different mat designs.

Duration of use: For long-term projects, composite or steel mats may offer better ROI than timber.

Budget: Timber mats are cheaper upfront, while composite mats provide longer lifespan savings.

Environmental regulations: Some regions require mats made from recyclable or low-impact materials.

Clean mats after use to prevent buildup of mud, oil, or chemicals.

Inspect regularly for cracks, rot, or structural damage.

Store mats flat in a dry, shaded area when not in use.

Use connectors to secure mats in high-traffic areas and prevent shifting.

Specifications of Mobile road coverage from polymer composite materials

| Product Type: - Mobile road coverage from polymer composite materials | |

| Dimensions:- Length, mm - Width, mm - Height, mm | 6130213088 |

| The effective surface area, (m²) | 12,00 |

| Weight, (kg) | 630 |

| Operating temperature range, (Сᵒ) | +50~-40Of +50 to -40 |

| Possibility of repeated use (number of times) | 20 |

| Guarantee of resistance to UV radiation | Meets the requirements DIN EN ISO 4892-3:2006. Plastics -- Methods of exposure to laboratory light sources -- Part 3: Fluorescent UV lamps |

| Preparatory work before installation | possibility of laying the cover on the terrain with an unevenness up to 0.5 m |

| Operation on sandy and clayey soils | YES |

| Operation in the marshy areas of the first and second type (without sand dumping) | YES |

| Restrictions on maneuvering technique | no limits |

| Equipment with locking connectors to fix the plates together | YES |

| Availability of the necessary tools and materials for each batch of plates of 30 pieces for assembly and dismantling works. Including lock joints, locks, sling lines, installation hooks, spanner wrenches, extractors, repair kits) | YES |

| Specification of the load on the plate | |

| Wheel, (т) | 120 |

| Axial, (т) | 60 |

| Tracked, (т) | 120 |

| Breaking stress at bending, MPa | 50-70Mpa |

| Breaking stress at compression, MPa | 30-35Mpa |

| Water absorption at temperature (23+-2)℃ during (24+-1) hours, % not more than | <2% |

| Frost resistance, loss of bending strength after 25 cycles of freezing at temperature(-40)℃ and thawing, % not more than | ≤10% |

| Resistance to petroleum products, loss of bending strength, % not more than | ≤10% |

If you have any question and inquiry of Event Flooring mat, please contact me freely: sunny@sdxxhg.com

Other related Products of Access Road Mats:

QuickMat: Light weight, Easy to move by man.

DuraMat: Heavy duty, work well for heavy truck.

BaseMat: Bigger Size and Fexible.

AmphiMat: With Overlapping design, only one manufacturer in China

Outrigger Pad: Keep heavy equipment in balance and protect the ground.

Industries

Established in 1989,located in Qingdao city of Shandong province, Shandong Ningjin Xinxing Chemical Co.,LTD. is the most professional manufacture of engineering plastics and the only manufacturer who has complete MATS system in China.

Phone

+86 189 0640 6469

Location

Liaohe Road, Ningjin Industrial Zone, Dezhou City, Shandong Province, China.

Copyright © Shandong Ningjin Xinxing Chemical Co., Ltd. All Rights Reserved |

Sitemap

| Powered by